Researchers working at Kaunas University of Technology (KTU) have developed a novel technology that can enhance the efficiency of organic solar cells.

Organic solar cells are composed of abundant organic elements like carbon, hydrogen, nitrogen, fluorine, oxygen, and sulphur. These raw materials are plentiful, inexpensive and can be easily recycled.

Although the organic photovoltaic (OPV) elements are lighter, more malleable, and less expensive to produce, their proficiency still falls behind that of other photovoltaic technologies, such as silicone, perovskite, and tandem solar cells. However, hopefully, this will change soon.

Developing organic solar cells

Towards the end of 2018, a team of Lithuanian chemists from Kaunas University of Technology manufactured a material, which autonomously assembles into a molecule-thick layer – known as a monolayer – and can cover a range of surfaces and functions as a hole-transporting layer in a solar element.

Until now, the self-assembling monolayers (SAMs) have been utilised to generate unparalleled perovskite/silicon and CIGS/perovskite tandem solar cells. However, the technology also demonstrated itself to be incredibly effective – reaching a nearly record-breaking 18.4 power conversion when applied in an organic solar cell – created by the team headed by Professor Thomas Anthopoulos at the KAUST University in Saudi Arabia.

“We made some modifications in the material used in SAM formation to tailor it for organic solar elements. However, our technology, offering a breakthrough approach towards photovoltaic elements’ production remains the same: the surface is dipped into a solution and a molecule-thick semiconductor layer is formed. The technology is cheap, efficient and versatile”, explained Dr Artiom Magomedov of KTU Faculty of Chemical Technology, the co-author of the invention.

Advancing photovoltaic technologies

As the materials produced by KTU scientists are now commercialised and widely accessible in the market for research groups and companies all over the world, this breakthrough will continue to improve the development of photovoltaic technologies.

“Last year, we noticed an article published by the researchers from KAUST, where they described they achieved very high efficiency of an organic solar cell while using our SAMs. We contacted the scientists and offered to collaborate in enhancing the capacities of the material. Due to the pandemic restrictions, all cooperation was remote – we sent the synthesised materials by post and our colleagues in Saudi Arabia built the organic solar cells and measured their properties”, commented Dr Magomedov.

The organic solar cell using Br-2PACz molecule-thin coating as a hole-transporting layer achieved a power conversion efficiency of 18.4%, which is presently amongst the highest in OPV technologies. Additionally, the electrode created was chemically stable, and after elimination of the SAM, it could be recycled and reused to assemble fresh highly-performing OPV cells.

The team highlighted that the utilisation of comparable SAMs may possibly be expanded in other applications such as light-emitting diodes, photodetectors, or organic transistors. According to Dr Magomedov, all different solar technologies that are currently being developed will find their positions in the market – as OPV cells are lighter, can be made transparent and flexible, they can be applied to charging drones, household electronics and for indoor photovoltaics. Currently, no OPV elements are mass-produced.

“The semiconducting properties of organic elements are lower than those of non-organic materials. Therefore, the achieved efficiency results are very impressive for everyone working in the field. After the publication, a Swedish company Dyenamo has already obtained the licence to produce our materials tailored for the organic solar elements, as they see the potential of this technology”, concluded Professor Vytautas Getautis, the Head of the KTU team.

The researchers’ findings have been published 23 June 2021 and can be accessed under the title ‘Outstanding organic solar cells’ performance achieved by using new technology’.

How organic solar cells (really) work

Organic solar cells have long been touted as lightweight, low-cost alternatives to rigid solar panels made of silicon. Dramatic improvements in the efficiency of organic photovoltaics have been made in recent years, yet the fundamental question of how these devices convert sunlight into electricity is still hotly debated. (Credit: US Army Africa/Flickr)

You are free to share this article under the Attribution 4.0 International license.

As scientists continue to debate how organic solar cells convert sunlight into electricity, a recent study suggests the predominant working theory is incorrect.

The findings, published in the journal Nature Materials, could steer future efforts to design materials that boost the performance of organic cells.

“We know that organic photovoltaics are very good,” says study coauthor Michael McGehee, a professor of materials science and engineering at Stanford University. “The question is, why are they so good? The answer is controversial.”

What causes the split?

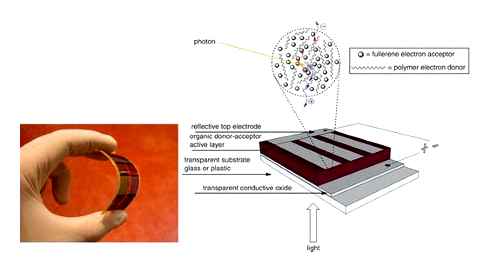

A typical organic solar cell consists of two semiconducting layers made of plastic polymers and other flexible materials. The cell generates electricity by absorbing particles of light, or photons.

When the cell absorbs light, a photon knocks out an electron in a polymer atom, leaving behind an empty space, which scientists refer to as a hole. The electron and the hole immediately form a bonded pair called an exciton.

The exciton splits, allowing the electron to move independently to a hole created by another absorbed photon. This continuous movement of electrons from hole to hole produces an electric current.

In the study, the team addressed a long-standing debate over what causes the exciton to split.

“To generate a current, you have to separate the electron and the hole,” says senior author Alberto Salleo, an associate professor of materials science and engineering at Stanford. “That requires two different semiconducting materials.

If the electron is attracted to material B more than material A, it drops into material B. In theory, the electron should remain bound to the hole even after it drops.

“The fundamental question that’s been around a long time is, how does this bound state split?”

The hot effect

One explanation widely accepted by scientists is known as the “hot exciton effect.” The idea is that the electron carries extra energy when it drops from material A to material B. That added energy gives the excited (“hot”) electron enough velocity to escape from the hole.

But that hypothesis did not stand up to experimental tests, according to the team.

“In our study, we found that the hot exciton effect does not exist,” Salleo says. “We measured optical emissions from the semiconducting materials and found that extra energy is not required to split an exciton.”

So what actually causes electron-hole pairs to separate?

“We haven’t really answered that question yet,” Salleo says. “We have a few hints. We think that the disordered arrangement of the plastic polymers in the semiconductor might help the electron get away.”

In a recent study, Salleo discovered that disorder at the molecular level actually improves the performance of semiconducting polymers in solar cells. By focusing on the inherent disorder of plastic polymers, researchers could design new materials that draw electrons away from the solar cell interface where the two semiconducting layers meet, he adds.

“In organic solar cells, the interface is always more disordered than the area further away,” Salleo explains. “That creates a natural gradient that sucks the electron from the disordered regions into the ordered regions. ”

efficient

The solar cells used in the experiment have an energy-conversion efficiency of about 9 percent. The Stanford team hopes to improve that performance by designing semiconductors that take advantage of the interplay between order and disorder.

“To make a better organic solar cell, people have been looking for materials that would give you a stronger hot exciton effect,” Salleo says. “They should instead try to figure out how the electron gets away without it being hot. This idea is pretty controversial. It’s a fundamental shift in the way people think about photocurrent generation.”

Contributors include researchers from the University of Potsdam; the Institute for Applied Photophysics; the University of California, Berkeley; the King Abdullah University of Science and Technology; the Colorado School of Mines; and the University of Oxford.

The Stanford Center for Advanced Molecular Photovoltaics and the US Department of Energy supported the work.

Organic Solar Cells and Photovoltaics: Structure, Functions, Price

Scientists all around the world are developing new technologies to make efficient use of solar energy. From roof-top solar panels to solar lights, there are numerous devices to help people generate electricity from sun rays.

Organic photovoltaics is the most recent development in this sector. over, these high-potential solar cells are the game-changers in how solar electricity is generated.

Although organic solar cells offer numerous benefits, many people are unaware of this innovative technology. In this blog, you will get familiar with the organic solar photovoltaic cells, their function, pricing, and various aspects of this recent solar technology.

What are Organic Photovoltaics Solar Cells?

Organic solar cells use organic electronics and carbon-based materials as semiconductors to generate electricity from solar energy.

They are also referred to as polymer solar cells or plastic solar cells. Although they follow the same process as traditional silicon solar panels for generic electricity, there is one significant difference between the two.

Unlike silicon solar panels, organic photovoltaics have a flexible structure. Therefore, they can easily fit multiple spaces and are also suitable for making solar power Windows.

Although this new technology requires more research and development, the wide range of applications is increasing its popularity and reliability already.

over, organic solar cells are less costly to produce. It means that more people will be able to install them without worrying about their budget.

Structure of Organic Photovoltaics Solar Cells

OPV or organic photovoltaics have a flexible structure due to carbon-rich compounds. As a result, they enhance PV cell functions like bandgap, colour, and transparency.

To create an OPV structure, organic compounds that easily dissolve in ink are printed on thin plastic layers.

These solar power generic cells are relatively less efficient and durable than conventional solar panels. However, they are less expensive too. It certainly results in their high production volume.

In addition, the plastic-based material of the OPV is easily applicable to a variety of surfaces and areas.

How do Organic Photovoltaics Solar Cells Function?

The function of organic photovoltaics is similar to polycrystalline and monocrystalline silicon solar cells.

They generate solar electricity with the photovoltaic effect. It means, they directly convert the sun’s rays into electricity at the atomic level.

- In the first step of the photovoltaic effect, the organic solar cells absorb sunlight in the form of energy known as photons.

- The cells then break the photons to loosen electrons.

- These free electrons flow to electron acceptors to create a direct current.

- The electrical current then transfers to the solar inverter.

- The solar inverter converts DC power into AC power for residential usage.

Different Types of Organic Photovoltaic Solar Cells Available in the Market

Polymer-based organic solar cells are categorised into three groups according to their production method. Have a look!

- Single-layer organic cells: In this type, the external circuit connects to two electrodes through a conductor. The difference in the functions creates an electrical field in the layers of the organic cells.

- Bilayer organic cells: This type of organic photovoltaics consists of multiple layers of cathode, acceptor, ITO, donor, and substrate. Bilayer organic solar cells split excitons for increased efficiency.

- Bulk heterojunction organic cells: In this type of organic solar cell, there are two transparent electrodes and one active layer to trap the solar energy.

Power Generation From Organic Photovoltaics Cells

OPV and PV follow a similar process of power generation. However, the low efficiency of OPV results in less power generation due to insufficient absorption of sun rays.

Nonetheless, they’re cheaper than other conventional solar cells. Hence, there’s definite future scope.

What is the Pricing of Organic Photovoltaic Solar Cells?

Organic photovoltaics technology is a revolutionary development in the sector of solar power generation.

The OPV harnesses solar energy to domestic power establishments at a highly affordable price. Although this technology is new and requires extensive research for development, the average cost of organic solar cells varies between INR 2,485/m2 to INR 7,456/m2.

Pros and Cons of Organic Photovoltaics Solar Cells

Organic photovoltaics offer the following benefits:

- The soluble organic molecules of organic solar cells facilitate an easy and less costly manufacturing process.

- The organic solar cells have adaptive and flexible structures, resulting in a large area of application. over, these lightweight structures are appropriate for use in Windows and doors that receive abundant sunlight.

- Manufacturers have a vast supply of building block materials for organic photovoltaics.

Cons of Organic solar cells:

- The efficiency of organic photovoltaics is comparatively lower than a conventional silicon solar cell. Generally, silicon solar cells offer 18-20% efficiency in the conversion of sun rays into usable electricity. On the other hand, an organic cell’s efficiency is estimated at around 8-12%.

- The organic materials of OPV degrade much faster than silicon. Therefore, OPVs are a little less durable.

Why Isn’t Solar Energy Popular?

Sun offers a sustainable source of energy to every part of the world. However, solar energy is not as widespread a process of generating electricity as it should be.

The following factors play a vital role in limiting the use of organic photovoltaics and PV system for solar power generation:

- Solar panels require a huge investment. Therefore, many economically backward groups find difficulty in investing in solar panels.

- The efficiency of organic photovoltaics is low. People need to install multiple organic solar panels to generate sufficient units of electricity. This requires enormous space.

- The generation of solar power directly depends upon the availability of bright sunlight. Conditions like storms and clouds can rob people’s access to continual electricity from the Sun.

That being said, applying for a solar subsidy provided by the government and EMI solutions provided by solar companies can nullify the financial constraints.

Conclusion

Organic photovoltaics is a promising system for generating sustainable energy. Many researchers are developing new ways to increase its efficiency.

It is highly expected that in the coming days, this technology will gain popularity.

over, the abundant material availability of organic photovoltaics makes it affordable. Almost everyone will be able to harness the benefits of sunlight to fulfil their daily power requirement.

FAQs

Q. How long do organic photovoltaics Solar Cells last?

Organic photovoltaics solar cells generally show less than 30% degradation in two months when exposed to harsh climatic conditions.

However, multiple searches are underway to increase the durability of these organic cells.

Q. What leads to the low efficiency of organic solar cells?

Organic cells are highly prone to recombination due to the increased attraction between carbon-based materials and electrons. This results in low efficiency of the organic solar compounds.

Q. What is the meaning of efficiency in organic photovoltaics?

The efficiency of solar cells means the amount of solar energy they can convert into usable electricity.

Therefore, an 8% efficiency means that the solar panel can convert 8% of the total sunlight it receives into an electric current.

Outstanding performance of organic solar cell using tin oxide

Organic solar cells have a photoactive layer that is made from polymers and small molecules. The cells are very thin, can be flexible, and are easy to make. However, the efficiency of these cells is still much below that of conventional silicon-based ones. Applied physicists from the University of Groningen have now fabricated an organic solar cell with an efficiency of over 17 percent, which is in the top range for this type of material. It has the advantage of using an unusual device structure that is produced using a scalable technique. The design involves a conductive layer of tin oxide that is grown by atomic layer deposition. The scientists also have several ideas to further improve the efficiency and stability of the cell. The results have been described in the journal Advanced Materials on 31 March.

In organic solar cells, polymers and small molecules convert light into charges that are collected at the electrodes. These cells are made as thin films of different layers—each with its own properties—that are stacked onto a substrate. Most important is the photoactive layer, which converts light into charges and separates the electrons from the holes, and the transport and blocking layer, which selectively directs the electrons towards the electrode.

Stability

‘In most organic solar cells, the electron transport layer is made of zinc oxide, a highly transparent and conductive material that lays below the active layer,’ says David Garcia Romero, a PhD student in the Photophysics and Optoelectronics group at the Zernike Institute for Advanced Materials at the University of Groningen, led by Professor Maria Antonietta Loi. Garcia Romero and Lorenzo Di Mario, a postdoctoral researcher in the same group, worked on the idea of using tin oxide as the transport layer. ‘Zinc oxide is more photoreactive than tin oxide and, therefore, the latter should lead to a higher device stability,’ he explains.

Although tin oxide had shown promising results in previous studies, the best way to grow it into a suitable transport layer for an organic solar cell had not yet been found. ‘We used atomic layer deposition, a technique that had not been used in the field of organic photovoltaics for a long time,’ says Garcia Romero. However, it has some important advantages: ‘This method can grow layers of exceptional quality and it is scalable to industrial processes, for example in roll-to-roll processing.

Scalable

The organic solar cells that were made with tin oxide deposited by atomic layer deposition on top show a very good performance. ‘We achieved a Champion efficiency of 17.26 percent,’ says Garcia Romero. The fill factor, an important parameter of solar cell quality, showed values up to 79 percent, in agreement with the record values for this type of structure. Furthermore, the optical and structural characteristics of the tin oxide layer could be tuned by varying the temperature at which the material is deposited. A maximum power conversion was reached in cells with a transport layer that was deposited at 140 degrees Celsius. This same result was demonstrated for two different active layers, meaning that the tin oxide improved efficiency in a generic way.

‘Our aim was to make organic solar cells more efficient and to use methods that are scalable,’ says Garcia Romero. The efficiency is close to the current record for organic solar cells, which stands around 19 percent. ‘And we haven’t optimized the other layers yet. So, we need to push our structure a bit further.’ Garcia Romero and his co-author Lorenzo di Mario are also keen to try making larger area cells. These are typically less efficient but are needed to step towards real-world applications and panels.

Improvement

The new solar cell with an impressively high fill factor is a good starting point for further development. Garcia Romero: ‘It may be a bit early for industrial partners to take this on; we need to do some more research first. And we hope that our use of atomic layer deposition will inspire others in the field.’ ‘We always strive to understand what is happening in a material and in a device structure,’ adds Professor Loi. ‘Here, we think that there might be room for improvement. In that process, our tin oxide transport layer is a great initial step.’ This class of solar cells may make an important extra contribution to the energy transition because of their mechanical properties and their transparency. ‘We expect that they will be used in a totally different way than silicon panels,’ says Loi. ‘We need to think broader and out of the box at the moment.’

Reference: Lorenzo Di Mario, David Garcia Romero, Han Wang, Eelco K. Tekelenburg, Sander Meems, Teodor Zaharia, Giuseppe Portale and Maria A. Loi: Outstanding Fill Factor in Inverted Organic Solar Cells with SnO2 by Atomic Layer Deposition. Advanced Materials, online 31 March 2023.

Types of photovoltaic cells

Photovoltaic cells or PV cells can be manufactured in many different ways and from a variety of different materials. Despite this difference, they all perform the same task of harvesting solar energy and converting it to useful electricity. The most common material for solar panel construction is silicon which has semiconducting properties. [2] Several of these solar cells are required to construct a solar panel and many panels make up a photovoltaic array.

There are three types of PV cell technologies that dominate the world market: monocrystalline silicon, polycrystalline silicon, and thin film. Higher efficiency PV technologies, including gallium arsenide and multi-junction cells, are less common due to their high cost, but are ideal for use in concentrated photovoltaic systems and space applications. [3] There is also an assortment of emerging PV cell technologies which include Perovskite cells, organic solar cells, dye-sensitized solar cells and quantum dots.

Monocrystalline Silicon Cell

The first commercially available solar cells were made from monocrystalline silicon, which is an extremely pure form of silicon. To produce these, a seed crystal is pulled out of a mass of molten silicon creating a cylindrical ingot with a single, continuous, crystal lattice structure. This crystal is then mechanically sawn into thin wafers, polished and doped to create the required p-n junction. After an anti-reflective coating and the front and rear metal contacts are added, the cell is finally wired and packaged alongside many other cells into a full solar panel. [3] Monocrystalline silicon cells are highly efficient, but their manufacturing process is slow and labour intensive, making them more expensive than their polycrystalline or thin film counterparts.

Figure 2. An image comparing a polycrystalline silicon cell (left) and a monocrystalline silicon cell (right). [4]

Polycrystalline Silicon Cell

Instead of a single uniform crystal structure, polycrystalline (or multicrystalline) cells contain many small grains of crystals (see figure 2). They can be made by simply casting a cube-shaped ingot from molten silicon, then sawn and packaged similar to monocrystalline cells. Another method known as edge-defined film-fed growth (EFG) involves drawing a thin ribbon of polycrystalline silicon from a mass of molten silicon. A cheaper but less efficient alternative, polycrystalline silicon PV cells dominate the world market, representing about 70% of global PV production in 2015. [3]

Thin Film Cells

Figure 3. A thin film solar panel composed of non-crystalline silicon deposited on a flexible material. [5]

Although crystalline PV cells dominate the market, cells can also be made from thin films—making them much more flexible and durable. One type of thin film PV cell is amorphous silicon (a-Si) which is produced by depositing thin layers of silicon on to a glass substrate. The result is a very thin and flexible cell which uses less than 1% of the silicon needed for a crystalline cell. [3] Due to this reduction in raw material and a less energy intensive manufacturing process, amorphous silicon cells are much cheaper to produce. Their efficiency, however, is greatly reduced because the silicon atoms are much less ordered than in their crystalline forms leaving ‘dangling bonds’ that combine with other elements making them electrically inactive. These cells also suffer from a 20% drop in efficiency within the first few months of operation before stabilizing, and are therefore sold with power ratings based on their degraded output. [3]

Other types of thin film cells include copper indium gallium diselenide (CIGS) and cadmium telluride (CdTe). These cell technologies offer higher efficiencies than amorphous silicon, but contain rare and toxic elements including cadmium which requires extra precautions during manufacture and eventual recycling. [3]

High Efficiency Cells

Other cell technologies have been developed which operate at much higher efficiencies than those mentioned above, but their higher material and manufacturing costs currently prohibit wide spread commercial use.

Silicon is not the only material suitable for crystalline PV cells. Gallium arsenide (GaAs) is an alternative semiconductor which is highly suitable for PV applications. Gallium arsenide has a similar crystal structure to that of monocrystalline silicon, but with alternating gallium and arsenic atoms.

Due to its higher light absorption coefficient and wider Band gap, GaAs cells are much more efficient than those made of silicon. Additionally, GaAs cells can operate at much higher temperatures without considerable performance degradation, making them suitable for concentrated photovoltaics. GaAs cells are produced by depositing layers of gallium and arsenic onto a base of single crystal GaAs, which defines the orientation of the new crystal growth. This process makes GaAs cells much more expensive than silicon cells, making them useful only when high efficiency is needed, such as space applications. [3]

The majority of PV cells, including those discussed above, contain only one p-n junction of semiconductor material which converts energy from one discreet portion of the solar spectrum into useful electricity. Multi-junction cells have 2 or more junctions layered on top of each other, allowing energy to be collected from multiple portions of the spectrum. Light that is not absorbed by the first layer will travel through and interact with subsequent layers. Multi-junction cells are produced in the same way as gallium arsenide cells—slowly depositing layers of material onto a single crystal base, making them very expensive to produce, and only commercially viable in concentrated PV systems and space applications. [3]

Emerging Cell Technologies

Electricity can be produced through the interaction of light on many other materials as well. Perovskite solar cells, named after their specific crystal structure, can be produced from organic compounds of lead and elements such as chlorine, bromine or iodine. They are relatively cheap to produce and can boast efficiencies close to those of commercially available silicon cells but they are currently limited by a short lifespan. Organic solar cells consist of layers of polymers and can be produced cheaply at high volumes. These cells can be produced as a semi-transparent film, but suffer from relatively low efficiencies. Dye-sensitized solar cells can be produced using semiconducting titanium dioxide and a layer of ‘sensitizer’ dye only one molecule thick. These cells boast modest efficiencies but cannot withstand bright sunlight without degrading. Quantum dots utilize nanotechnology to manipulate semiconducting materials at extremely small scales. ‘Nanoparticles’ consisting of a mere 10,000 atoms can be tuned to different parts of the solar spectrum according to their size, and combined to absorb a wide range of energy. Although theoretical efficiencies are extremely high, laboratory test efficiencies are still very low. [3]